Tips to prevent air bubbles

There are four main reasons why resin bubbles occur:

Understanding what causes bubbles in epoxy resin can help prevent them from occurring in the first place.

There are four main reasons why resin bubbles occur:

- not following best practices when working with resin

- cold temperatures

- pour too thick layer

- the piece you pour resin over, releases trapped air

Bubbles are one of the biggest problems we hear about here at ArtResin: we have some great tips on how to prevent bubbles and how to fix them if they've already appeared!

Let's take a look…

How to prevent resin bubbles

1) Best practices when using resin:

Using a gas burner:

When mixing your resin and hardener you create a lot of bubbles as you stir: these bubbles must be eliminated after you pour your resin or they will harden right into your artwork. The best way to get rid of bubbles is with a gas burner: the flame heats the resin surface immediately, thinning the resin and allowing the bubbles to burst. If you are intimidated by the thought of using a gas burner... please don't be. Nothing is as effective as a flame to get rid of bubbles and once you use one, you'll wonder what you ever did without it!

Can heat guns help?

A heat gun can be useful in some resin applications, such as flow art, where it can be used to create cells. To eliminate bubbles, however, a heat gun simply doesn't get hot enough to do the job effectively. It can blow resin around and can even blow dust all over your wet piece. We always recommend using a gas burner to get rid of resin bubbles.

The only exception is when removing bubbles from a silicone mold: in this case, a flame can be too intense and if you overburn it can even damage the mold.

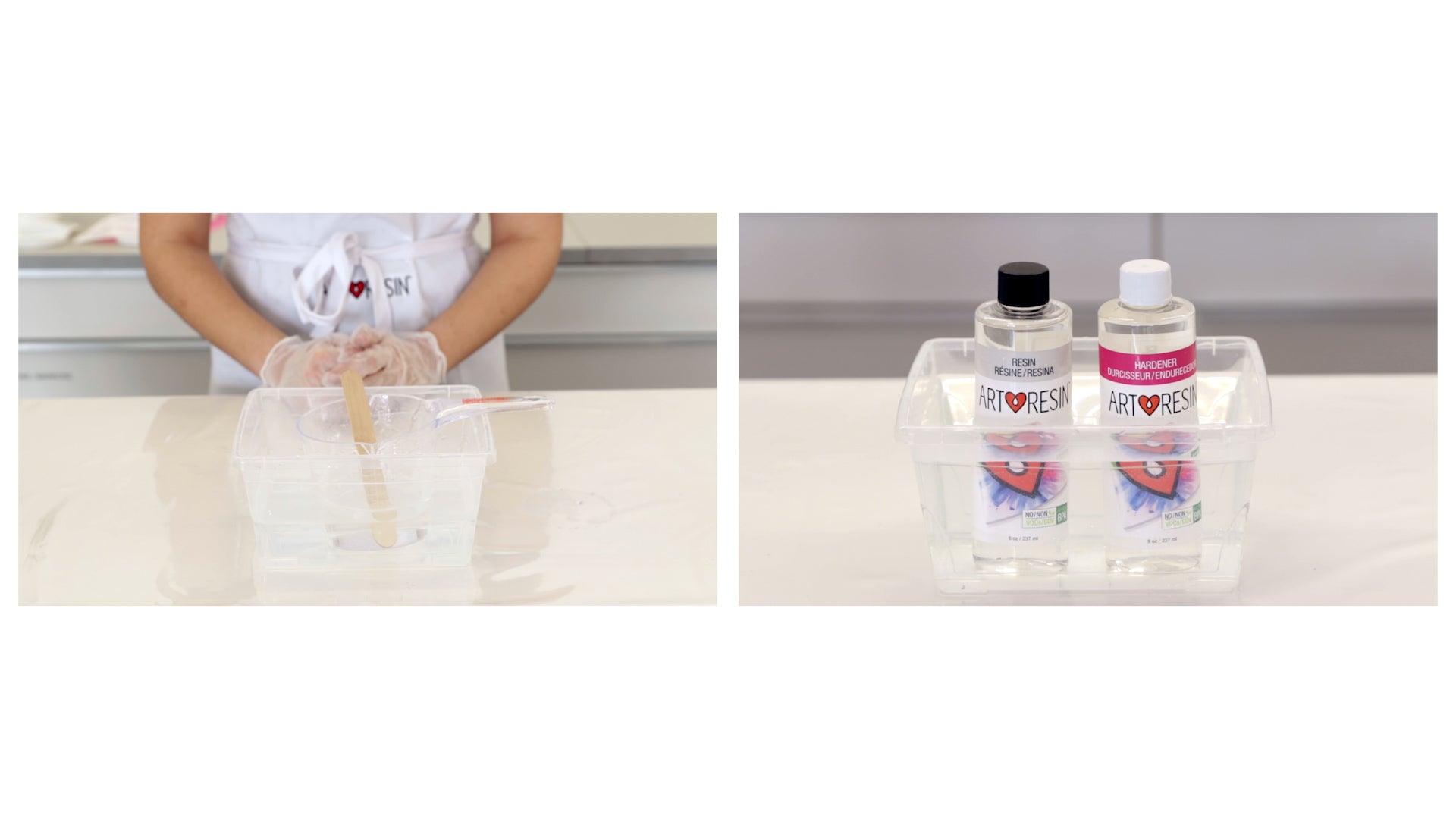

Whisk your resin:

Mixing resin is where the magic happens: when you stir, a chemical reaction begins between the resin and hardener that will eventually transform the mixture from a liquid to a solid. Although you need to mix the two parts thoroughly for at least 3 minutes, you want to be sure not to whip your resin like you're whipping cream or egg whites. Whisking the resin induces more bubbles than necessary, which can lead to problems such as overburning.

Don't whisk your resin - instead, stir slowly and deliberately, scraping the sides and bottom of your mixing container as you stir. You'll get some bubbles, of course, but nothing that a quick burn or two with the gas burner can't handle.

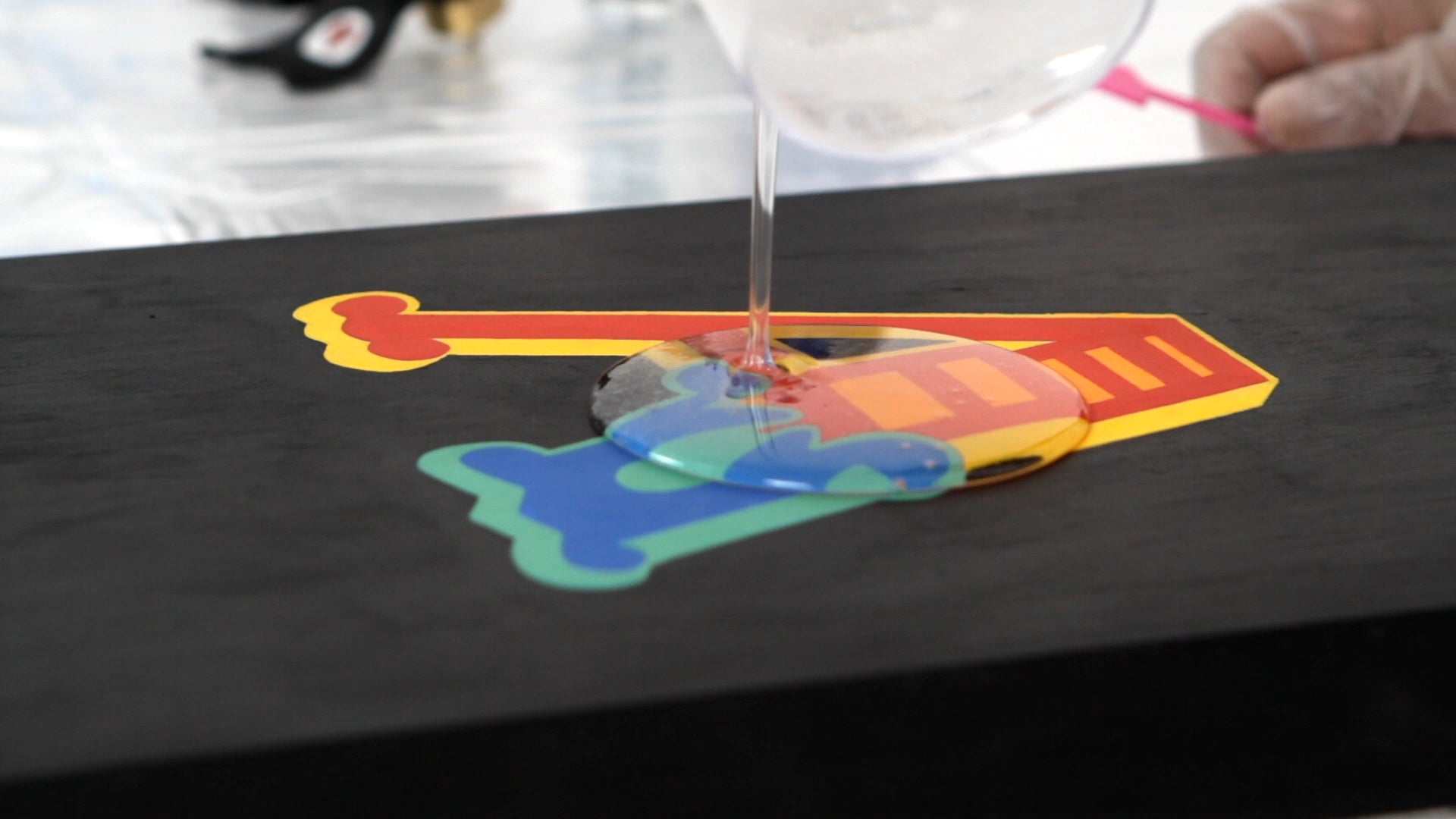

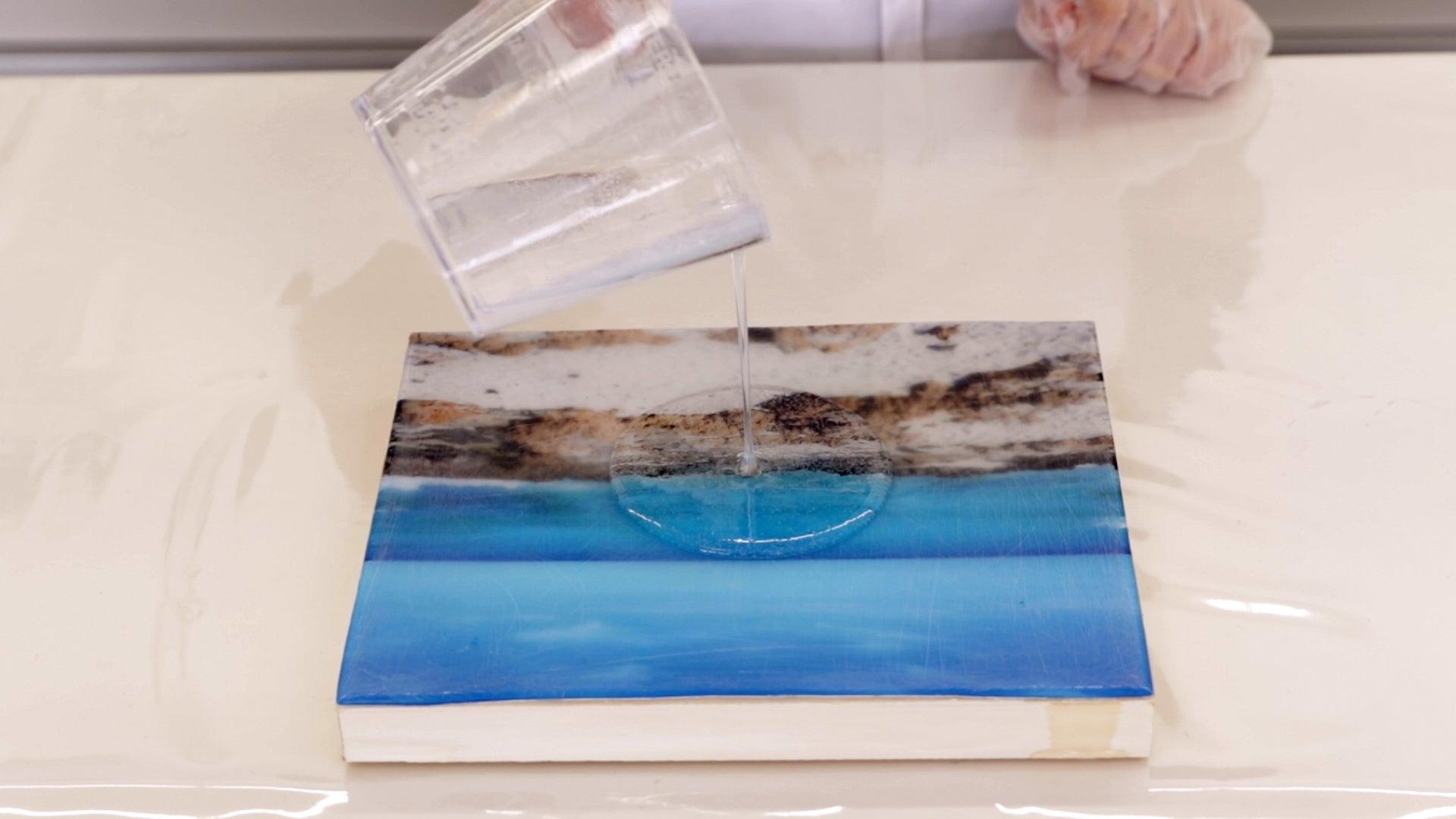

Drain your resin:

Just as whisking your resin can cause unnecessary bubbles, so can pouring your resin onto your artwork. Instead, place your mixing container close to the surface of your piece and slowly pour your resin mixture out.

2. Cold temperatures

Did you know that ArtResin epoxy resin loves warm temperatures? It's true! In fact , the ideal temperature for both your ArtResin and your work surface is slightly warmer than room temperature: 24-30C. At these temperatures, ArtResin has a crystal-clear appearance, a honey-like texture, and flows and spreads with ease. On the other hand, cold resin is thick, difficult to work with and has a cloudy, milky appearance. You know your resin is too cold when it has a sticky consistency, making it difficult to pour and spread.

It also takes on a frothy, milky appearance due to thousands of microbubbles that are virtually impossible to burn out.

If your resin is cold, you need to bring it to room temperature before using it. You can do this by leaving the resin bottles in the room to come up to room temperature or you can try a warm water bath.

Place your bottles of resin and hardener in a container of warm water: the water doesn't need to be very hot...about what you would use to bathe a baby.

Since heat accelerates curing, always warm the bottles BEFORE measuring and mixing to avoid premature curing of the mixture.

Leave the lids on to prevent water from mixing into your resin or hardener: water accidentally getting into your resin mixes will cause a cloudy cure.

Do not submerge the bottles and dry them thoroughly before opening.

Resin at room temperature or slightly warmer is flexible, clear and easy to pour and spread.

💡TIP: If you use a water bath to heat your ArtResin, keep in mind that heat promotes faster curing: this means your 45 minute working time will be reduced by around 10 minutes. It also means that the resin can thicken and harden in the cup if you let it sit out on the work surface while you finish your artwork. Get everything ready first, then measure and mix your resin and pour right away. Don't let your hot resin stay in the mixing cup!

3) Pour too thick:

ArtResin was designed as a surface coating for artwork and was formulated to be poured in thin applications: this gives bubbles the chance to escape to the surface of the resin to burn out. The maximum thickness that we recommend pouring is 2cm. When ArtResin is poured thicker than 2cm, bubbles may stick and you may not see them your hardened resin.

If you want a thicker layer of ArtResin, we recommend pouring in layers, waiting 3-5 hours between each layer.

4) Release trapped air:

Porous, organic materials such as wood, leaves, fabric and even paper can "breathe" air. When you coat these materials with resin, the air bubbles release into the resin in the form of bubbles, sometimes hours after you pour and burn.

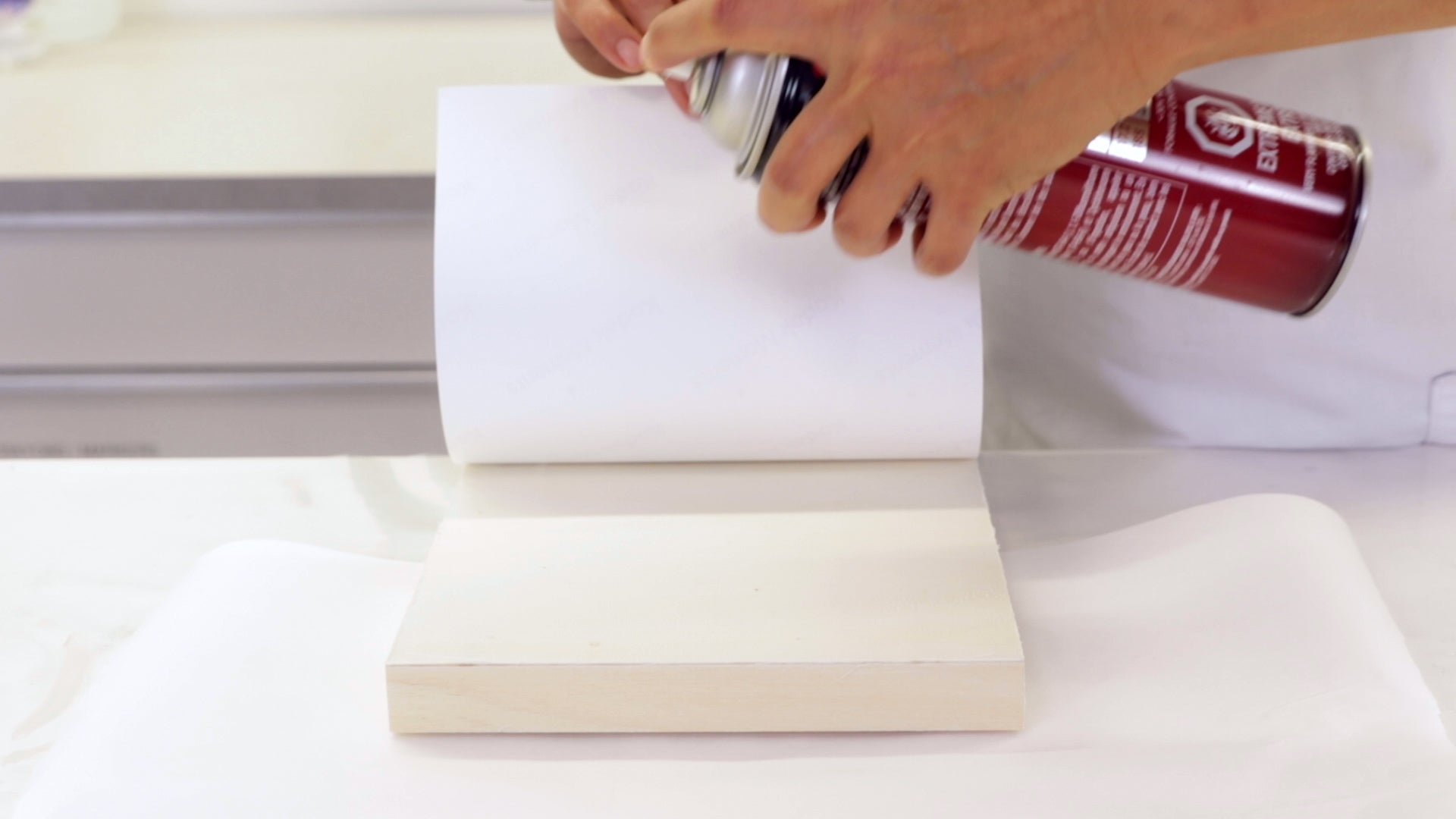

To prevent air bubbles from escaping into your resin, seal natural materials such as wood and paper by brushing or spraying sealant before resin treatment.

Sealing creates a barrier and prevents trapped air from escaping and creating bubbles in the resin.

Poorly mounted prints can also be a source of unwanted air bubbles. Always make sure your prints are evenly mounted on the panel. Whether you choose a glue stick or a spray adhesive, avoid air pockets by applying an even amount of glue.

Here's how we prefer mounting pressure: use a spring clamp to secure the pressure and panel in place. Don't forget to place a clean piece of paper under the clamp to protect your print!

Apply an even amount of glue over one half of the panel, paying particular attention to the perimeter. We prefer to use spray adhesive.

With a clean piece of paper in place to protect your print, gently roll a brayer over the surface to eliminate any air pockets and to ensure a tight bond between the print and the panel. Pay particular attention that the edges of your print are well adhered to the panel to prevent air from escaping and to prevent resin from seeping in.

Reverse the print and repeat the process on the other half. Once the print is securely mounted, you are ready to resin!

💡 TIP: Some papers are more porous than others and can allow the resin to penetrate. We always recommend testing on a piece first so you know if you need to seal your paper before resin treatment: sealing creates a barrier, preventing the resin from being absorbed into the paper.

How to get bubbles out of resin?

If you come back the next day to check your work and find a bubble in your resin, don't worry! Thankfully, epoxy resin is very forgiving, meaning many problems (including bubbles) can be fixed with a simple sanding and re-casting.

Here's what you need to do:

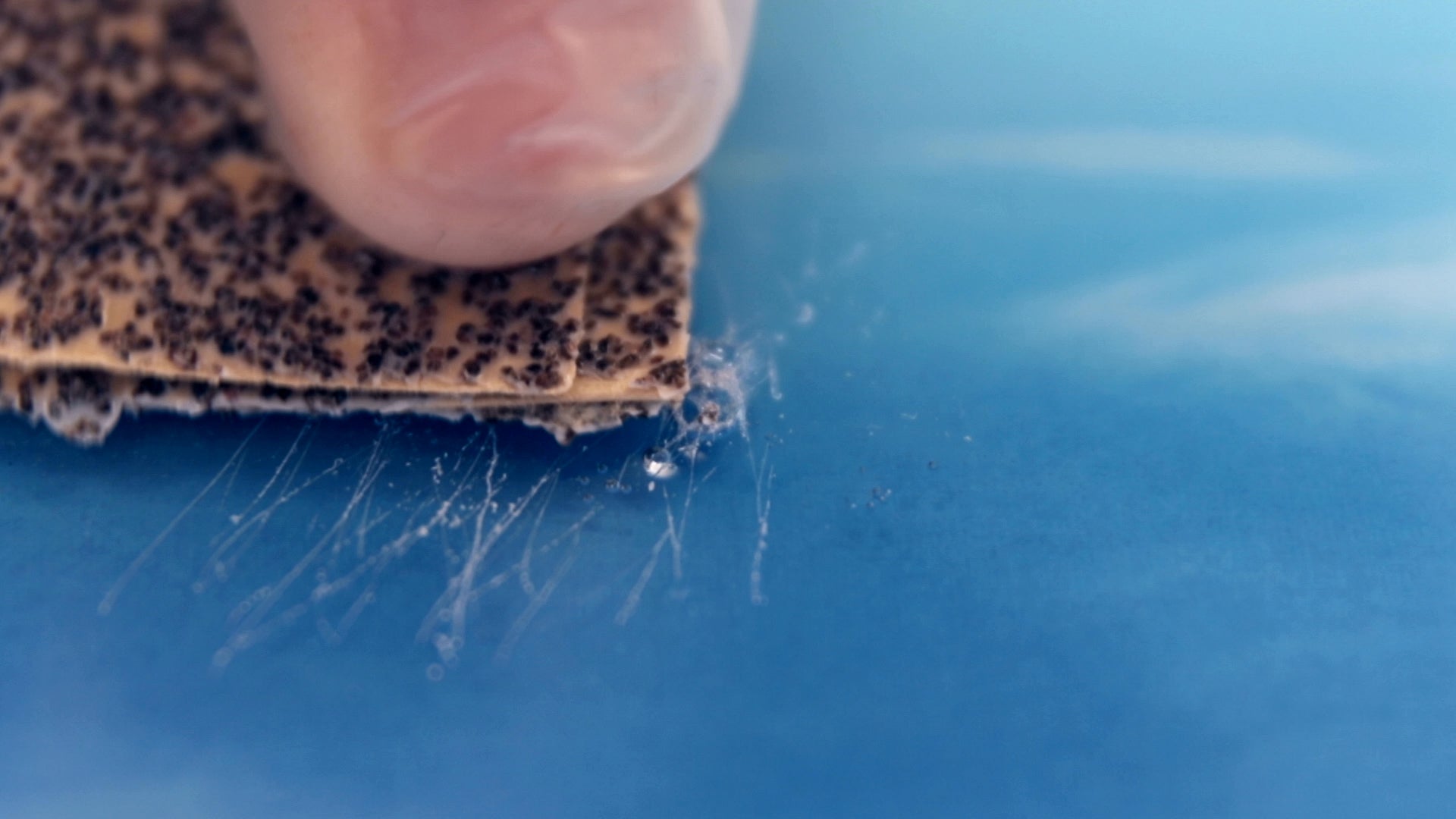

1) Sand

Sand down the entire surface of your piece, paying particular attention to sanding out the bubbles. The purpose of the sanding is to create a tooth for the fresh resin layer to be added here, so it is very important that you sand the entire piece and use a coarse sandpaper, like 80 grit. After you sand, your piece will look scratched, but don't worry! ArtResin will fill in all those scratch marks and your piece will look crystal clear again.

2) Dry

Use a damp paper towel to wipe away any dust. Wipe as many times as necessary - your surface must be completely free of sanding residue before you pour your new layer of resin. Feel free to use a can of compressed air or brush your surface with a soft brush to ensure there is no sanding residue left on your piece.

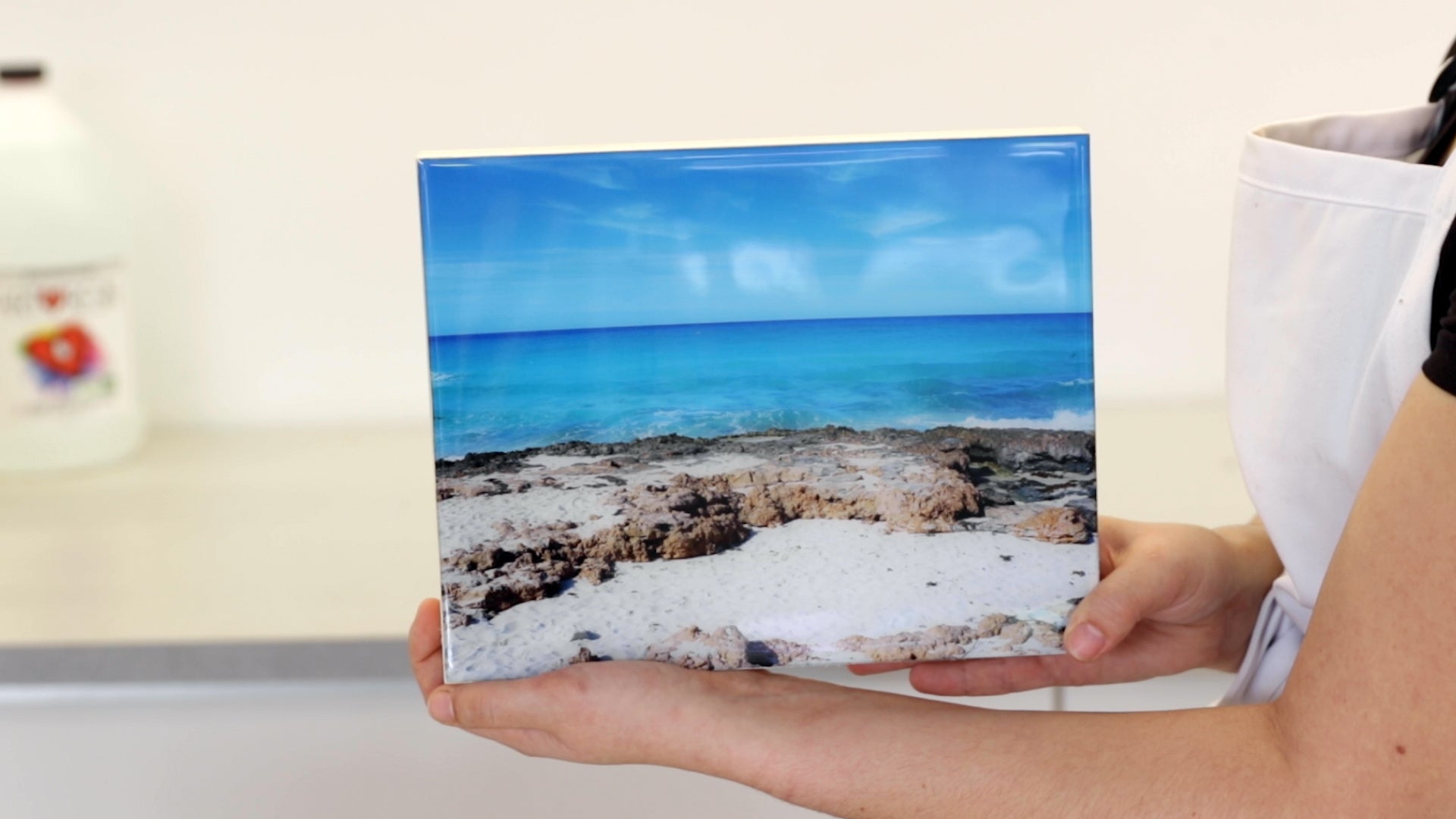

3) Pour

Mix a new batch of carefully measured and carefully mixed ArtResin according to the directions, and apply a new coat of resin over your sanded and wiped piece. Spread as desired, burn out any bubbles, cover and wait 24 hours for a touch dry cure and 72 hours for a full cure.

See?

When your fresh layer of resin cures, you won't see any sanding marks - just a wonderfully glossy, crystal clear ArtResin finish. You would never know you ever had any bubbles in your work!

So remember….

- Use a gas burner

- Stir and pour carefully

- Use room temperature ArtResin

- Mount carefully

- Thicken if necessary .

.. and if you already have annoying bubbles in your cured resin, follow our simple steps to get rid of them. We hope this was helpful

please leave any questions or comments below!